SELECTED

ISSUE

|

|

Leisure Management - Single-use plastics

Everyone’s talking about

|

|

| Single-use plastics

|

As researchers discover

plastic has now entered the

human food chain, is it time

to stop using single-use

plastics in the spa industry?

Is it more expensive, and

if so when does the health

of humans and the planet

become more important

than the bottom line? Kath

Hudson investigates

|

Up to 8 million tonnes of plastic is dumped into the sea every year LeQuangNhut/shutterstock

|

|

|

Between California and Hawaii there’s a plastic mass three times the size of France. While we continue to dump 8 million tonnes of plastic into the sea every year there’s no chance of this diminishing and the impact on sealife is devastating.

Microplastics are causing another catastrophic issue. These tiny pieces of broken plastic come from microbeads used in some cosmetics, or are released into the environment when synthetic materials, such as those used in some spa linen and towels, are washed. Microplastics have been identified in fish and tap water, so it’s no surprise that they’ve also now entered the food chain.

Governments around the world have recognised the problem and are starting to make changes. The US, Canada and the UK have banned the use of microbeads in personal care products. With only 9 per cent of plastic ever produced being recycled, the European parliament has voted for a ban on single-use plastics, including plates, cutlery, straws and cotton buds, by 2021. By 2025, EU states will also be obliged to recycle 90 per cent of plastic bottles.

It’s only a matter of time before plastic used in skincare packaging and single-use plastics in spas, such as the wraps used for thousands of spa and hotel amenities, come into question.

Times are changing and the cosmetics industry is going to have to adapt, especially as leading operators like Six Senses, The Oaks at Ojai in the US and Titanic Spa in the UK say they no longer want single-use plastics. So what are the alternatives? Can single-use plastics be replaced without hitting the bottom line? We ask the industry…

|

Warrick Burton managing director, Titanic Spa

Warrick Burton Last March we eliminated single-use plastics, after being horrified to find more than 500 plastic water bottles at the bottom of our pond. A plastic bottle takes 1,000 years to biodegrade! We immediately replaced them with water stations and reusable cups. We’ve replaced plastic straws with a biodegradable alternative made of seashells.

We constantly challenge suppliers to reduce their single-use plastic packaging – it’s surprising what can be achieved if you ask. Also, we work with specialist recycling partners, to ensure properly recycling. We try to remain as paperless as possible, directing customers to digital materials rather than printouts.

“Moving away from plastic may increase costs slightly, but it’s often surprising how little the increase is”

Several years ago we switched from microfibre to cotton robes and linen by BC Softwear and we use OTEX to launder instead of detergents. This washes on a cool temperature and delivers continuous ozonated water, leaving linen 100 per cent disinfected. It also means we have no transport to and from laundry services.

Moving away from plastic may increase costs slightly, but it’s often surprising how little the increase is, so we would certainly encourage other spas to make efforts. We were only given one planet earth and looking after it should be our number one priority – not budgets. If we don’t change the way we run our businesses, we will be doing irreparable damage.

Warrick Burton opened Titanic Spa, the UK’s first eco spa, in 2005

Stephan Helary, CEO, Terres D’Afrique

Stephan Helary Banning single-use plastics might hit the bottom line but, nonetheless, it’s a change which needs to be made and everyone will have to pay the price: suppliers, operators and spa goers.

All of our retail products and most of our professional products are either in glass or aluminium containers. However, for large sizes – more than a kilo – we use recyclable plastic. Glass is heavy, so more expensive to ship, which means the cost is higher than operators are currently prepared to pay.

I dislike using plastic packaging in general. It can never be recycled to the same grade and carcinogenic plastic molecules can be transferred into the product. Glass is a better option, because it doesn’t interact with the product. However, raw materials are used to recycle it [which requires more energy and resources], plus it’s heavy, breakable and costly.

“The cosmetics industry is the biggest user of plastic, so going forward we will have to make changes”

Aluminium is light, protects the product well and is easily recyclable: 80 per cent of all aluminium ever produced is still in circulation and cans can be back on the shelves in three weeks. The downside is that it takes a lot of energy to make it in the first place and it dents very easily.

The cosmetics industry is the biggest user of plastic, so going forward we will have to make changes. The speed with which we have given up straws shows there’s an appetite from consumers to make changes, which will put pressure on businesses. However, change will need to be enforced by governments, because self governing is not working.

Terres d’Afrique is an organic and sustainable African skincare range. It supplies over 30 leading spas

Emma Roberts head of sales and business development, Voya

Emma Roberts Finding sustainable packaging is our biggest challenge and we’re constantly looking for new technology and innovations. The price of biodegradable plastic alternatives is prohibitively high, but we’re confident this will reduce going forward.

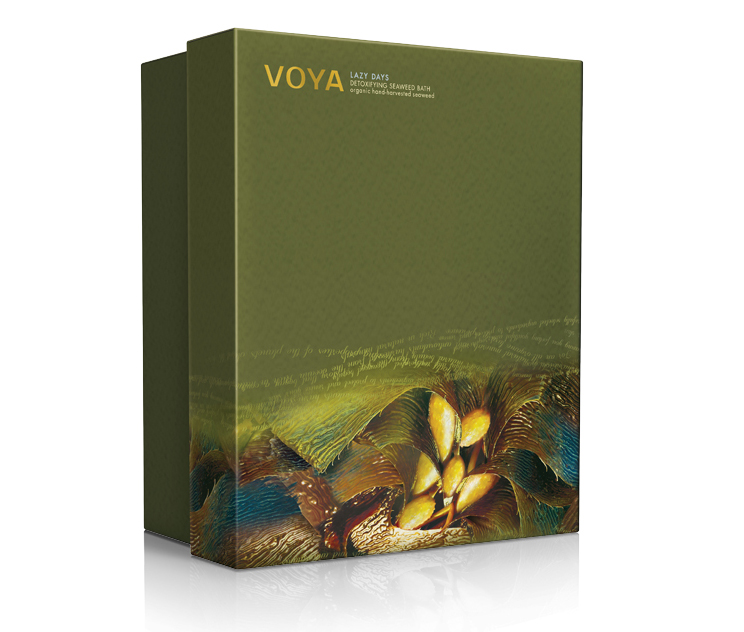

Sustainability is one of Voya’s core beliefs and we’ve got rid of plastic wherever possible. All outer packaging is made from recyclable card. Our body range contains a special blend of FSC-certified pulps using our own harvested seaweed and is printed with vegetable and mineral inks. It costs around 80 per cent more for this packaging, but it’s one of our brand values. The packing chips we use are 100 per cent biodegradable and dissolve in water.

“Sustainability is one of Voya’s core beliefs and we’ve got rid of plastic wherever possible”

The one area in which we are still trying to find a solution is for our top selling product, Lazy Days seaweed. Because the seaweed needs to be kept completely dry, as well as meet stringent pharmaceutical standards, we haven’t yet been able to find inner packaging which can meet our brief. We wanted to replace the inner storage bag with muslin, but this was rejected by the standards agency. Added to this, it comes in a net, which our customers love, because it’s so convenient, but which we want to stop using. Using a biodegradable plastic net is currently too costly, so we’re consulting with our customers about doing away with it completely.

Organic seaweed-based spa brand Voya currently has more than 450 accounts worldwide

Voya’s outer packaging is made from seaweed pulp

Charmaine Lang founder and CEO, The Madison Collection

.jpg)

Charmaine Lang Although there’s increasing recognition of the damage which single-use plastics cause, an area of which there’s far less awareness, and even ignorance, is microplastics – but they’re just as much a cause for concern. Spas are heavy users of towels and linens, and those containing synthetic material shed multiple fibres into the waterways during the laundry process, as well as ending up in landfill unable to biodegrade.

The Madison Collection towels are free of both microfibres and chemicals. They’re high quality and hard wearing, but also biodegradable at the end of their lifespan. We now supply to hundreds of spas, and it’s getting easier, but 10 years ago it was a tough sell. Big, fluffy towels spelled luxury, and that’s what spas wanted. My towels are thinner but, due to the fine quality cotton used, are super absorbent.

“Millennials will ultimately drive operators to make ethical choices”

Initially operators weren’t interested in buying a thinner towel, which is also slightly more expensive, but I convinced them by the operational cost savings. As the towels are half the thickness of a normal towel they require less storage, twice as many can be put in the washing machine at once and they dry quickly. After four months, operators offset the upfront investment and start to save money.

Millennials will change things going forward. They appreciate quality and environmental credentials and they will ultimately drive operators to make ethical choices.

The Madison Collection, a brand of luxury, sustainable towels, launched in 1999 and now works with clients in 40 countries

Operators are slowly seeing the cost-saving benefits of using eco-friendly linen

How are other suppliers tackling plastic and recycling?

• Aromatherapy Associates uses 100 per cent FSC-accredited card for its cartons and is phasing in recycled material for all plastics, glass tubes and bottles. It’s target is to use recycled plastic in more than 50 per cent of products and to make all plastic material 100 per cent recyclable

• Caudalie uses some recycled plastic packaging, as well as some biodegradable sugar cane packaging. Where possible, alternative materials, such as glass and wood, are used

• From this year (2019), all of Clarins’ tubes will contain 25 per cent recycled plastic and all caps of 50ml jars will be 100 per cent recycled plastic

• Around 90 per cent of the paper and paper board used by Comfort Zone is recycled and about 40 per cent of the plastic used is recycled or bio-based (coming from renewable resources). Its new suncare product, launching in mid 2019, will be packaged in recyclable plastic

Labels are made from fabric with the brand name woven into them

• During the next 12 months, Phytomer will be launching a new line of three products in green packaging, made from sugar cane. There are plans to progressively roll out recyclable plastic for all new tubes

•Vinoble’s packaging is now made entirely from sustainable materials – glass, wood and fabric – with no plastic being used. Labels for products are made of fabric with the brand and product names woven into them in plain lettering

Vinoble’s packaging is made entirely from sustainable materials

How are other suppliers tackling plastic and recycling?

Stéphanie Thévenot As we produce up to 150 million units of spa accessories and amenities a year, we’re working on a number of initiatives to reduce our waste and be eco responsible.

We’re looking at reducing the plastic used for our accessories through the development of vegetable-based products and paper cotton buds. Additionally, we’re reducing the amount of cardboard packaging used and removing single-use plastic bags from most accessories.

In other cosmetic packaging, we’re prioritising the use of recycled plastic or plant based packaging, made from sugar cane. There’s a large cost impact as we have to invest in new moulds for the sugar cane packaging. Sourcing and testing new materials is also very time consuming. What’s more we’re developing solid shampoos, shower gel, conditioner and body lotion. These require no plastic use and water consumption is reduced during production.

"We're working on a number of initiatives to reduce our wasteand be eco responsible"

Some of the brands we work with need transparent packaging and sugar cane can’t be transparent, so we’re trying to find different solutions. We’re working on oxy-biodegradable packaging, where additives are included to increase their biodegradation to 85 per cent in four years. However, this throws up other issues, as bio-additives may get banned in Europe.

Recycled plastic is one of the most environmentally sound materials and is cost competitive to use, but traceability is an issue. We can’t track what it contained before, so there are concerns that something might transfer from the plastic into the product.

Groupe GM distributes guest amenities in over 70 countries. It also provides white label amenities for spa brands such as Clarins, Deep Nature and La Sultane de Saba

Group GM is one of the biggest providers of guest amenities worldwide

|

|

|

| Originally published in Spa Business 2019 issue 1

|

|

|

|